The processing of Impruneta clay represents the very best of traditional Italian craftsmanship, a knowledge rooted in history and handed down with dedication. Extracted from the quarry of the Poggi Ugo terracotta furnace, this precious clay is selected with the utmost care and worked exclusively by hand, using techniques that have been consolidated over the centuries by master craftsmen.

“Posting” is the oldest of the techniques and is carried out entirely by hand, without the aid of any mould or support. It is also the most complex technique, entrusted entirely to the skill and experience of the master. The work begins with the creation of the base of the object on a support: a ball of clay is flattened by hand to give it a circular shape, leaving the edges slightly raised to receive the “lucignolo”, a strand of clay previously worked and stretched. This technique, also known as “colombino”, involves the application of successive strands of clay around the base, which gradually merge to form a compact and resistant artefact.

This is followed by the delicate stages of plastering, smoothing and finishing, carried out with the utmost skill to ensure harmony and precision in the decorative details.

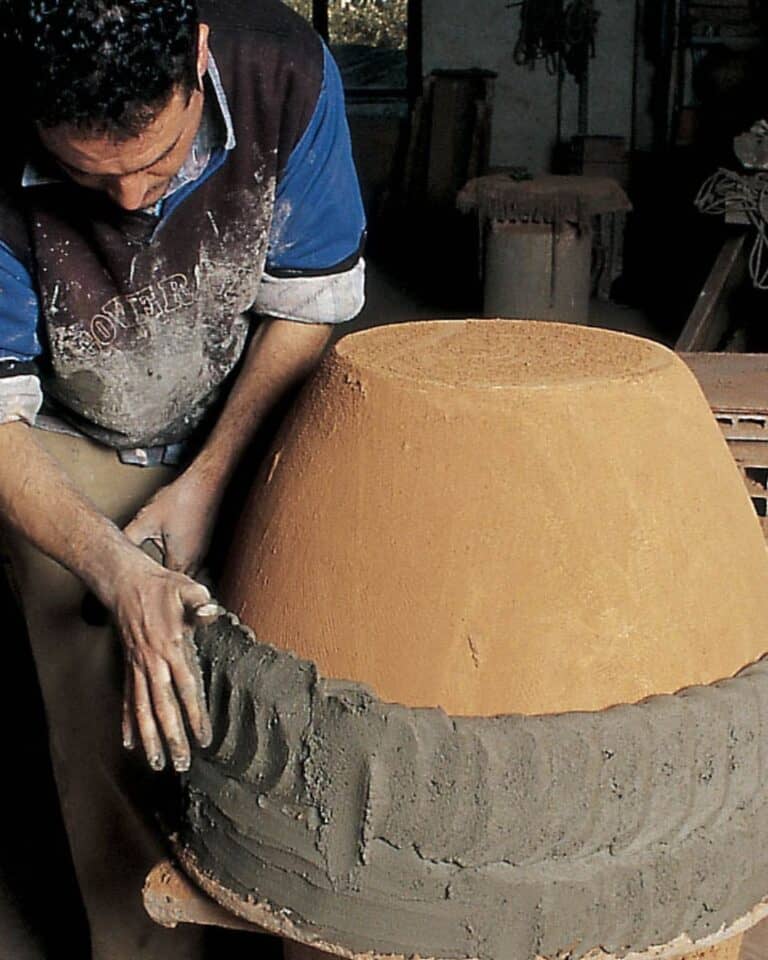

Another working technique is called the ‘shell’ technique. In this method, the artefact is made using a terracotta or plaster mould sprinkled with terracotta powder to prevent the clay from sticking. The clay is pressed by hand from the outside and the lucignolo is placed and applied around the mould. The element remains stationary while the craftsman, moving backwards, turns around the object and presses the clay. Once this stage is completed, the artefact is turned upside down on a support and the internal mould is removed, leaving a “shell” that is finished with seams and decorations, depending on the model to be made.

The casting process uses plaster moulds into which the clay is pressed by hand to reproduce the shape of the artefact. Once the clay has reached a suitable degree of drying, the walls of the mould are removed, revealing the vase already defined in all its decoration and shape. At this point, the artefact is carefully smoothed and finished in every detail. Casting in plaster moulds allows statues, risers, benches, fountains, cache-pots and busts to be modelled with precision, guaranteeing a high quality result.

At every stage of the production process, the skill and passion of the craftsmen are reflected in the quality of the finished artefact, an authentic expression of tradition and craftsmanship excellence. The processing of Impruneta clay in Poggi Ugo’s terracotta kiln is a benchmark in the sector, preserving ancient techniques and transforming each creation into a timeless work of art.